文章和案例研究

干燥谷物或油菜籽的超高效方法

The drying of grains and oilseeds is critical for downstream processing and storage as it prevents caking, agglomeration, spoilage and degradation of material. Controllability of the drying process is important to compensate for changes in the feedstock. Excessive drying of grains and oilseeds is undesirable and results in weight loss, whereas too much moisture can lead to degradation and numerous quality issues during storage and penalties at sale. Varying weather and process conditions call for the need for more efficient and flexible methods of drying grains and oilseeds. Also, solids have different limits on temperatures that they can be heated up to and varying ideal moisture content for storage.

Natural drying is not always an option and many variations of the air drying method have been used. The drying process is governed by typical factors like ambient conditions outside, relative humidity, temperature, grain texture, sensitivity to heat, moisture content and toughness of the grains.

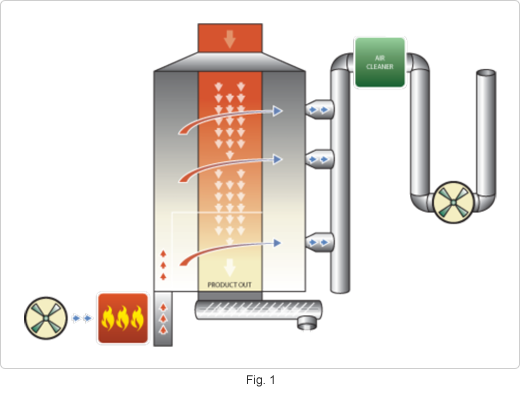

Conventional methods for drying grains and oilseeds typically use high volumes of hot air that are blown through the bed of grains. Use of hot air as the heating media as well as for moisture removal limits the efficiency of this technique. Large volumes of air must be heated for heat transfer and as the air picks up moisture from the grains and oilseeds the temperature of air drops and the air reaches saturation. Because of this, large volumes of air are required and the larger the volume of air used the more energy that is expended; much of this energy is lost up the stack. (Fig. 1). Many drying techniques have thermal efficiencies as low as 30%。 Also, the distribution of air through the grain beds and silos is often not ideal leading to non-uniform heat transfer and drying.

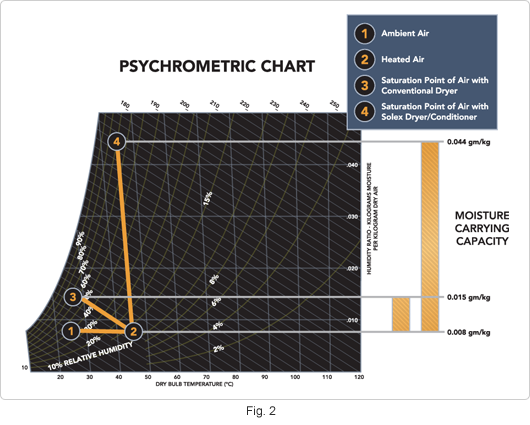

The use of indirect heat - through hot water or steam - can radically reduce the volume of air, consumption of energy and emissions for drying grains and oilseeds. If heat is available from a waste heat source, this can further add to the energy efficiency of the drying process. The plate heat exchanger design incorporating cross airflow for removal of moisture uses indirect heating of the grains or oilseeds through plates. This reduces the demand for a large volume of hot air and keeps the air temperature constantly high, which enables the air to carry increased amounts of moisture before reaching saturation (Fig. 2).

This technology is unique in the sense that it combines the science of heat transfer and thermal modeling with the knowledge of mass flow characteristics of bulk solids. The result is a thermally efficient technology which provides precise predictability, control and flexibility of performance. Moreover, consistent product quality is achieved as the equipment is designed for uniform heat transfer, ideal mass flow and uniform drying throughout the grain or oilseeds bed.

Plate bank heat exchanger dryers (Fig. 3) are recommended for any manufacturing facility looking to gain green points for environmentally friendly technology use. Installation of such dryers, as pre-conditioners or residual dryers, will reduce emissions and load on otherwise energy intensive dryers, thus improving the overall energy efficiency of the facility and ultimately increase production capacity.

询问专家

有问题?

需要更多信息?

我们随时准备提供帮助。